The Impact of Nanotechnology on Antifreeze

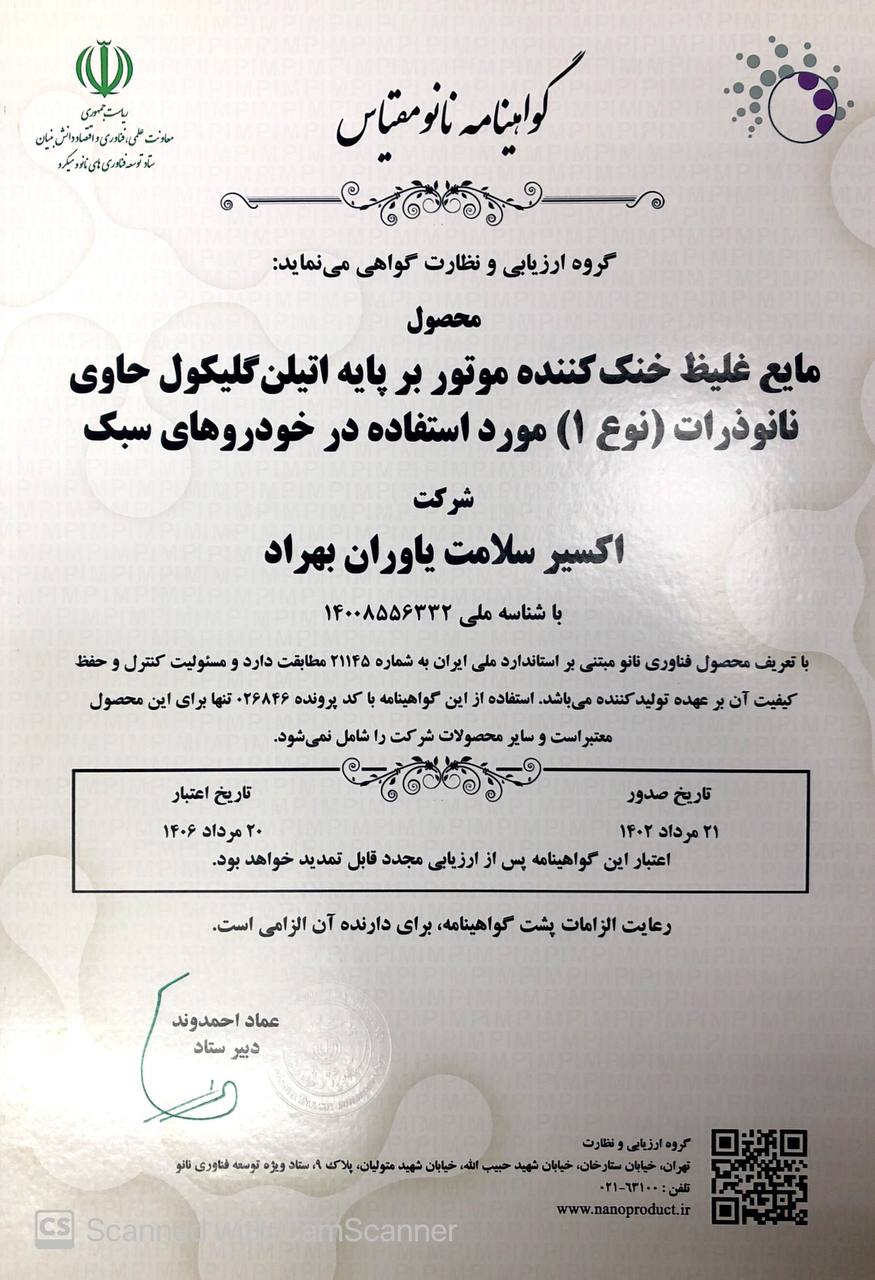

Exir Salamat Yavaran Behrad Company is the only manufacturer of antifreeze using nanotechnology, holding a patent, standard license, and official approval from the Nanotechnology Development Headquarters. This product has been introduced to the market as a new generation of engine coolants.

This product creates better properties in vehicle radiators compared to conventional antifreezes and coolants available in the market, resulting in improved vehicle engine performance and reduced wear and maintenance costs. The enhanced properties due to the presence of nanoparticles in Mooksi Antifreeze will be discussed below.

Improved thermal conductivity of the coolant

Pure antifreeze or a mixture of water and antifreeze under normal conditions has limited ability to transfer heat between the vehicle engine and the coolant. As a result, the engine operates at higher temperatures, preventing the vehicle from reaching optimal fuel efficiency.

Mooksi Antifreeze, utilizing nanoparticles, has achieved a 20% increase in thermal conductivity compared to conventional antifreezes. This enhancement improves the radiator’s heat exchange efficiency with the engine, optimizing engine operating temperature and enhancing combustion performance.

Significant reduction of corrosion on aluminum alloy surfaces

Maintaining aluminum alloy as the primary material in vehicle radiators is critically important, as it extends the cooling system’s lifespan and reduces long-term vehicle wear.

By leveraging nanotechnology, Mooksi Antifreeze reduces corrosion on aluminum alloy surfaces—a key parameter in national and international antifreeze quality standards—by 40% compared to conventional antifreezes.